The perfect filter for you

1.

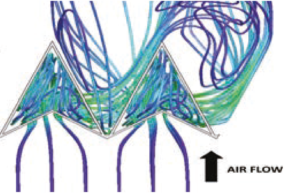

Binks filters use a combination of impingement and inertia separation to capture the overspray droplets suspended in the airstream passing through it.

The larger droplets tend to impinge and be retained by the front V shaped surface of the filter, preventing the bounce back effect of overspray. Whilst the accelerating air stream carries the overwhelming majority of the mid and smaller sized droplets through the network of circular holes distributed across the face of the filter.

2.

The forward momentum of the rapidly moving droplets separates them from the air stream which makes four quick and violent directional changes and so, deposits the droplets into the deep interior V pockets formed by each pleat.

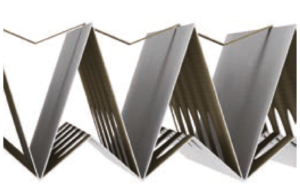

Our filter delivers important benefits to spray booth operators applying most industrial coatings and adhesives. Because the accordion style, stapled pleated construction captures overspray efficiently, last three to five times longer than ordinary dry filters and contributes to an improved, brighter working environment.

3.

One of the common problems experienced with traditional mesh filters occurs when they are used for slow drying coatings. During the time they take to dry, the constant airflow can drag out the still wet particles trapped in the mesh and re-launch them to migrate through the system.

The Binks filter design has in effect created a blind alley into once the droplets are driven; they are permanently trapped and cannot be re-launched into the air stream. Another added benefit to our filter is its high capacity for overspray holding. This results in a lower frequency of filter change, lower booth maintenance, meaning that fewer filters are required to be in stock, making them more cost effective. The holding capacity is a direct result of the size and depth of the filter pocket, a full 6cm deep.

4.

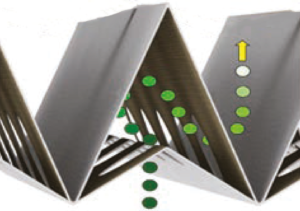

The opposing picture shows the Binks filter construction, which includes on the rear side an expansion strap to ensure the correct spacing of 8 corrugations to every foot (30.4cm) guaranteeing optimum and superior filter performance.

Additionally, because the superior ability of the Binks filters to hold a high capacity of overspray, the fluctuation in resistance to airflow is absolutely minimal over the life of the filter.

5.

Consequently the static pressure increases only slowly with the accumulation of paint, enabling a uniform airflow around the parts that are being coated, and more importantly clean air environment for the sprayers.

The construction of the Binks filter consists of two pieces of strong recycled cardboard, formed in to an accordion structure, stapled together for strength and rigidity throughout the assembly. The stapled assembly, coupled with the tight folds and crisp cutting of the holes promotes the optimum airflow through the filter, whilst obtaining the best entrapment of overspray.

Finally the rigidity of the structure and the precise arrangement of the holes along the middle of the front face, the sides of the rear face, and with the deliberate misalignment of the two, combine to create a product of true benefit.